OVALMATIC

MODEL

E8700

WIRE TYING MACHINE

The model E8700 Tying Machine is all-electric offering AC Vector Drive technology at an economical price. The E8700 is based on the venerable E9700 product line and shares many common parts.

Features and Benefits

ALL ELECTRIC WIRE TYING FUNCTIONS

No hydraulic oil leaks or clean up

TRACK

Proven low friction passive track design

AC VARIABLE FREQUENCY DRIVES

Closed loop control for Twister and Feed/Tension Unit gear motors

ON BOARD PLC HMI (TOUCHSCREEN)

Features easy operation with built-in diagnostics and maintenance tools

OPEN DESIGN

Allows easy access for inspection and maintenance

SAFE 24 VOLT DC

Control design with E-stop and master control relay

TWISTER HEAD

All functions are cam and gear driven to maintain cycle timing

NO TWISTER HEAD ADJUSTMENT

KEYED COMPONENTS

Standard Specifications

TYING WIRE RECOMMENDED

Ovalmatic® Quality Tying Wire

ELECTRICAL SERVICE

380-575 VAC, 3PH, 50/60 Hz. WYE with solid ground, 7.5KVA supply.

Transformer may be required.

Excluding conveyor power requirements.

ELECTRICAL MOTORS

Feed/Tension. 4.0kW (5 HP) NORD gear motor with NORD VFD

Twister Head. 1.5 kW (2 HP) NORD gear motor with NORD VFD

Conveyor Drive. 2 1.5 kW (2 HP) 380-575 VAC 3PH, 50/60Hz

All motors are supplied with equipment.

Variable frequency conveyor drives are customer supplied.

ELECTRICAL INTERLOCKS

Standard. Discrete I/O. 120 VAC or 24 VDC

Optional. Allen Bradley Ethernet I/P or Siemens Profibus.

ELECTRICAL CONTROL

Allen Bradley Control Logix 5370 series with Maple Systems HMI

Optional. Siemens 1200 Series PLC with Maple Systems HMI

Control Voltage. 24 VDC

ELECTRICAL COMPONENTS

All components meet CE/EL/CSA standards

PNEUMATICS

Required for auto air blast.

5.5-6.9 Bar, 28 L/min. (80-100PSIG, 1 SCFM)

Minimum filtration requirements: particulate filtration to 5 Microns with moisture removal and oil removal to 1PPM. Instrument air is strongly recommended where available.

Optional. Wire Lubricator.

Optional. Twister Pinion Lubricator.

MACHINE WEIGHT

653 kg (1,400 lbs.)

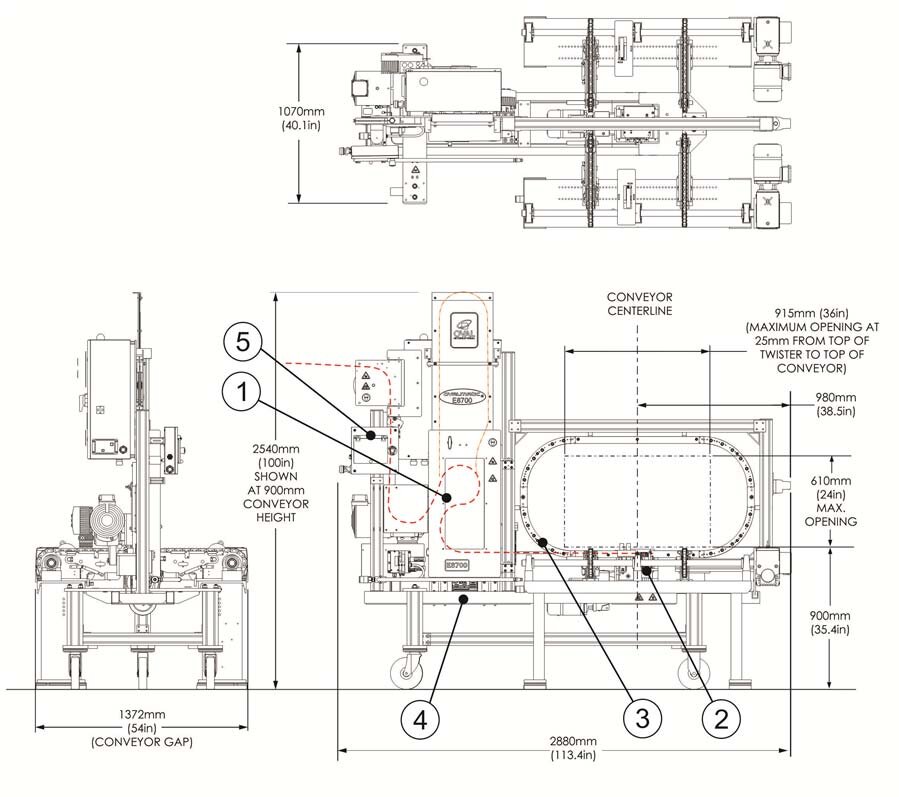

MACHINE HEIGHT

2,540 mm (100 in.) at 900mm (35.43 in.) minimum conveyor height

MACHINE WIDTH

2,880mm (113.4 in.) excluding coil carrier dispensing station

CONVEYOR

Powered forward/reverse, 27 meters/minute (90 feet/minute) standard.

CONVEYOR GAP

Standard: 1,372 mm (54 in.)

CONVEYOR WEIGHT

Standard: 636 kg (1,400 lbs.) per pair

CONVEYOR HEIGHT

Standard: 900 mm (35.43in) 500mm (19.68in minimum)

STANDARD BALE OPENING

915 mm x 610 mm (36 x 24 in.)

OVAL International® specifications are subject to change without notice.

RIGHT HAND STANDARD ARRANGEMENT

LEFT HAND STANDARD ARRANGMENT

OVALMATIC® COMPONENTS

The core of the Unityer is built on five Ovalmatic® components:

Feed and Tension Assembly

Twister Assembly

Track Assembly

Frame Assembly

Control Assembly

Each of these assemblies is designed to provide maximum accessibility for inspection and maintenance function.

ALL ELECTRIC DESIGN

All tying functions are electrically driven using closed loop AC drive technology.

Feeding

Tensioning

Gripping

Twisting

Cutting