OVALMATIC

MODEL

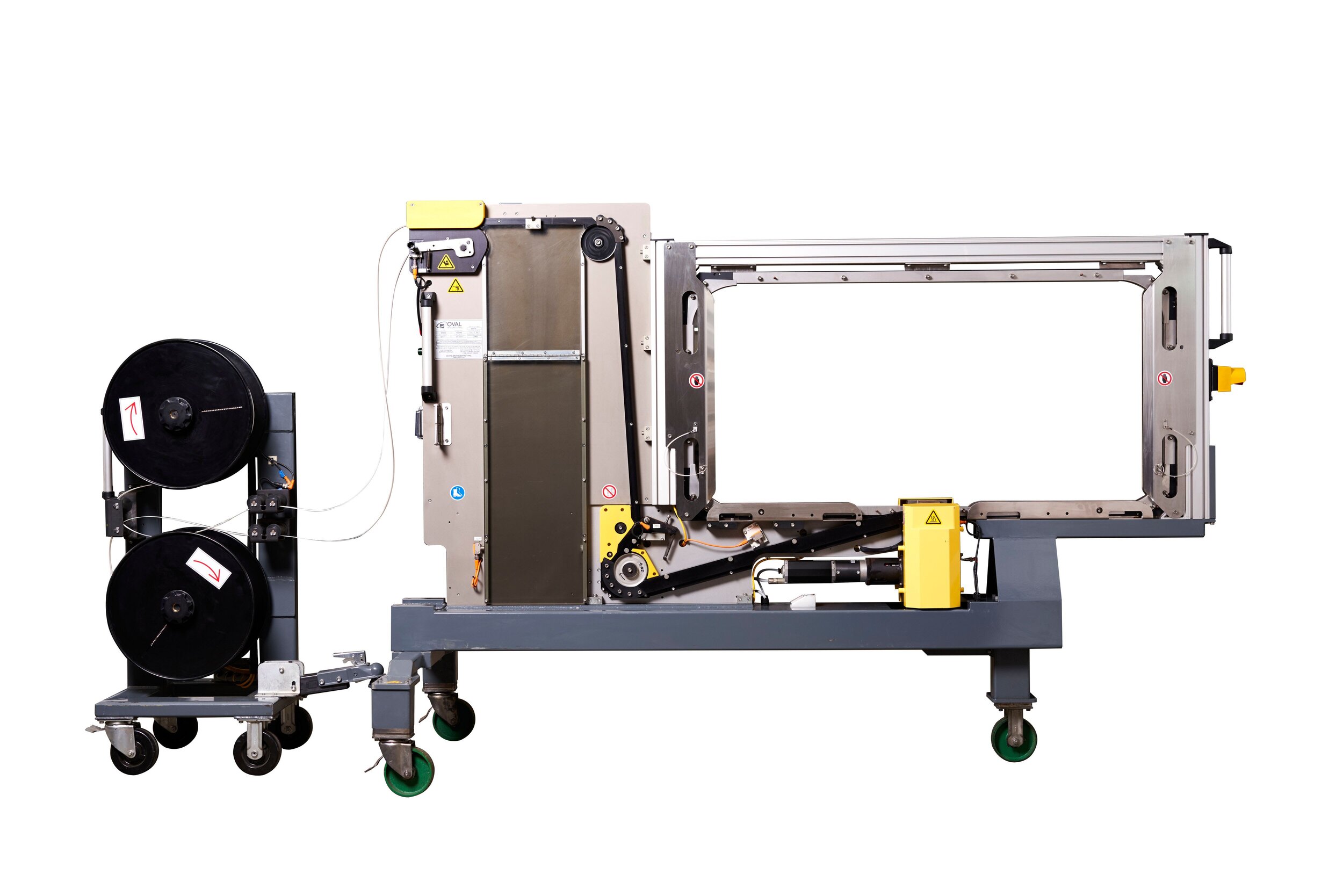

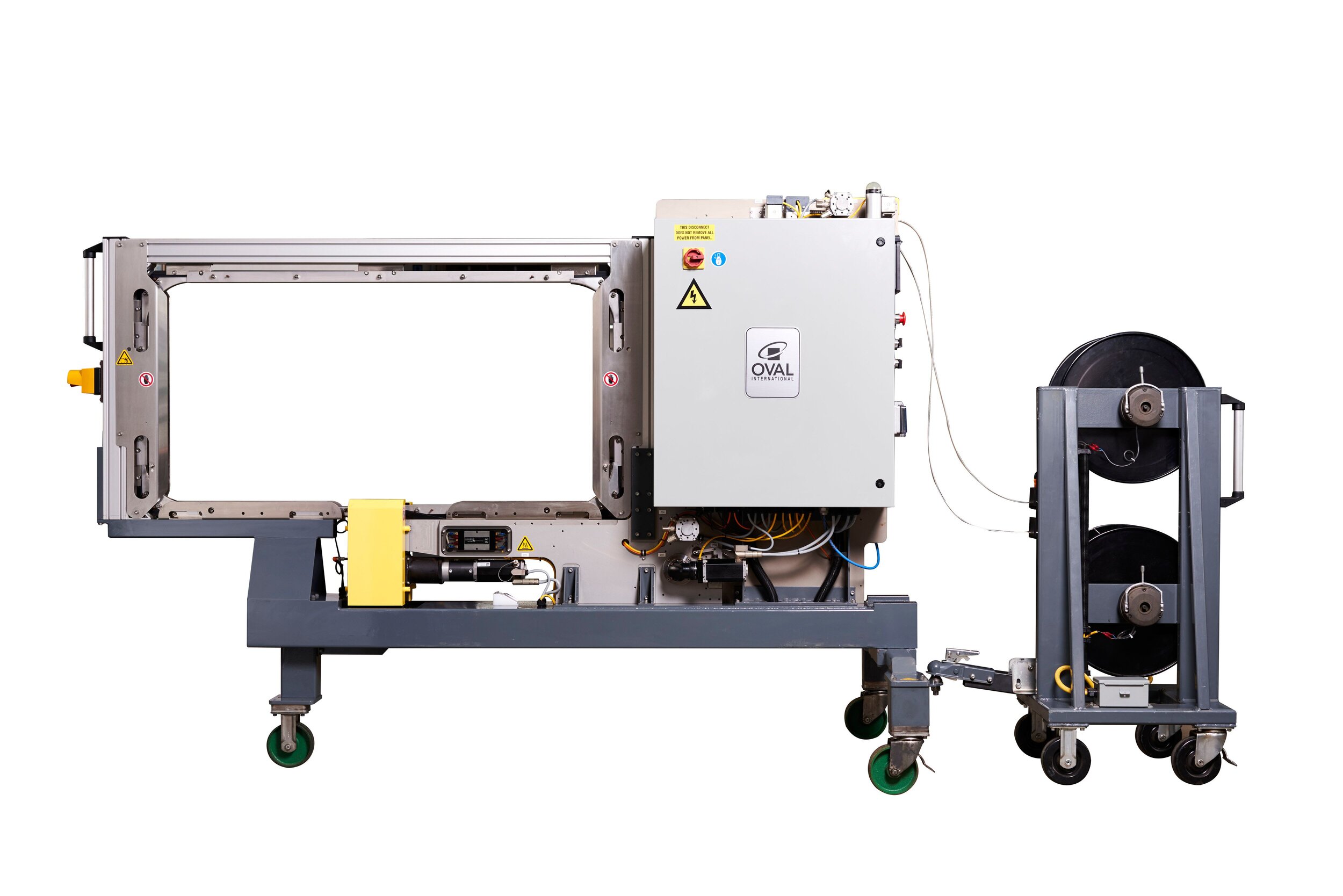

E9800

PAPER STRAPPING MACHINE

OVAL International offers the most advanced paper strapper in the pulp industry. The Model E9800 is an all-electric strapping machine designed specifically to apply Ovalmatic Quality repulpable strap.

Features and Benefits

SERVO DRIVES

Brushless DC servo gear motors provide smooth operation and high performance. Servo gear motors are directly coupled eliminating belts, chains, clutches and brakes in the drive system.

TOP FEED ACCUMULATOR

Easy load auto feed and eject, high capacity accumulating chamber, moist strap tolerant, large radius assisted corners

AUTO COIL EXCHANGE

Automatic coil change allows for continuous operation without immediate operator attention.

HMI/CONTROL PANEL

High quality color touch screen provides access to diagnostics, optional features, trouble shooting, maintenance prompts and parameter settings.

Records operational history

PAPER STRAP COIL

Coil weight approximately 40lbs (18kg)

Coils can be manually loaded onto the coil dispenser by a single operator without any special equipment

OPTIONAL CONFIGURATIONS

Several versions are available to fit into existing bale lines.

CLAMSHELL TRACK

Track sections overlap to ensure positive and reliable feeding

Open construction provides ready access

Rugged arch construction

Solid track mounting

Large radius corners for reliable strap feeding

SEAL HEAD

Large seal area

High sealing force for stronger seals

Large diameter cams and rollers for long service life

Servo driven

Strap cut at seal to reduce strap waste

FRAME

Constructed for the demanding pulp mill environment

Wide outrigger for superior stability

Compatible with virtually all conveying systems

Supplied with high quality finish

Standard Specifications

PAPER TAPE RECOMMENDED

Ovalmatic® Quality 19mm (.75in.) width x 1mm (.04in.) thick

ELECTRICAL SERVICE

100-250 VAC, 1PH, 50/60 HZ, 1KVA supply

(excluding conveyor power requirements)

ELECTRICAL MOTORS

Feed/Tension. 48 VDC, 220W, Dunkermotoren Servo motor

Second Tension. 48 VDC, 330W, Dunkermotoren Servo motor

Accumulator. 48 VDC, 220W, Dunkermotoren Servo motor

Seal Head. 48 VDC, 440W, Dunkermotoren Servo motor

Conveyor Drive. Two 1.5 kW (1.35 HP) 208-575 VAC 3PH, 50/60Hz, reversible SEW gear motors

All motors are supplied with equipment.

Variable frequency conveyor drives are optional.

ELECTRICAL INTERLOCKS

Standard. Discrete I/O

Optional. Ethernet and Profibus

ELECTRICAL CONTROL

Allen Bradley Micrologix 1400 with Maple Systems HMI with Ethernet capability

Control Voltage. 24 VDC

Optional controllers available.

ELECTRICAL COMPONENTS

All components meet CE/UL/CSA standards

ELECTRICAL WIRING

Proximity Switches with connectors. 0.21-0.82mm² (24-18 AWG) stranded cable

Standard. 0.82mm2 (18 AWG) stranded cable

Primary. 2.082 (14 AWG) stranded cable

MACHINE WEIGHT

423 kg (930 lbs)

MACHINE HEIGHT

1,553mm (61in) at 534mm (21in) minimum line height

MACHINE WIDTH

2,891mm (113in) excluding dispenser

DISPENSER WEIGHT

118 kg (260lbs.) empty

150 kg (340lbs.) full

CONVEYOR HEIGHT

534 mm (21 in.) minimum.

MAXIMUM BALE OPENING

12,19 mm x 610 mm (48in.x24in.)

OVAL International specifications are subject to change without notice.PAPER STRAPPING PACKAGING SYSTEM

We can help you achieve your corporate goal of having a trouble-free, fast and efficient pulp baling operation

Ovalmatic® E9800 Paper Strapping Machine

Installation and start-up assistance

After Start-up service, including scheduled onsite service and emergency service

Onsite training of personnel

Continuous research and development with ongoing improvements

Ongoing availability of Ovalmatic® quality packaging materials and spare parts

Guaranteed compatibility with packaging supplies and equipment.

OVALMATIC QUALITY REPULPABLE PAPER BALE STRAPPING

Fully repulpable to meet Tappi UM213 test as confirmed by independent testing

Manufactured from bleached Kraft paper using virgin NBSK

Strap Coils are easily handled and loaded onto an automated coil dispenser, by a single operator

Heat sealed using water soluble adhesive

Meets FDA criteria for food grade paper