OVALMATIC

MODEL

9500

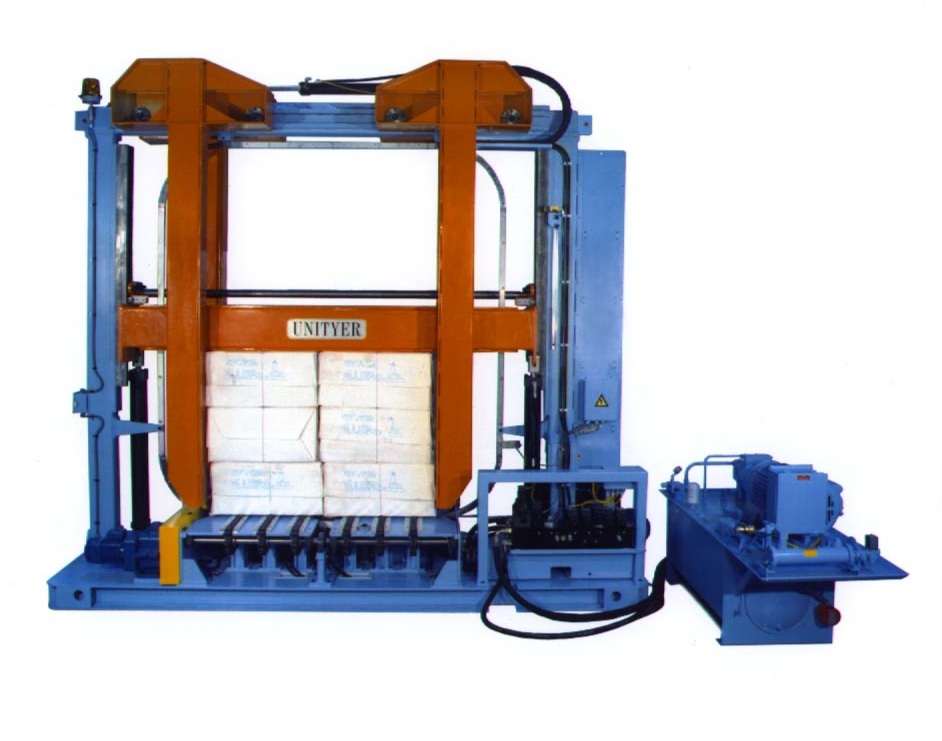

UNITYER®

The model 9500 Unitying Machine is hydraulically operated using hydraulic directional valves on-board and an off-board HPU. The 9500 is based on the venerable 9000 Unityer first introduced in the early 1970’s and shares many common parts.

Features and Benefits

Heavy duty frame built to withstand industrial environments.

Low Friction Track: Proven low friction passive track design requires no lubricants- no contamination of pulp

High efficiency designed feed and tension system

Easy to thread Wire Dispenser minimizes tangles

Ovalmatic® floating wire gripper has unique, maintenance-friendly, spring load design and is easily accessible

Precision wire tension proven reliable in all operating conditions

Simple, single stroke, direct-acting twister head

Self-monitoring control system

Single conveyor drive uses SEW gear motor allows precise pulp alignment

Top compactor equalizes down force using a rack and pinion arrangement and Side Compactor is centered on pulp bales- no sideways dragging of units

Standard Specifications

TYING WIRE RECOMMENDED

Ovalmatic® Quality Unitizing Wire-

Sized to meet customer requirements.

ELECTRICAL SERVICE

Unityer Tying Machine. 208-575 VAC, 3PH, 50/60 Hz, 5KVA

Compacting Station. 208-575 VAC, 3PH, 50/60 Hz

Excluding conveyor and hydraulic unit power requirements

ELECTRICAL MOTORS

Conveyor Drive. 2 1.5 kW (2 HP) 208-575 VAC, 3PH, 50/60 hZ reversible SEW gear motor.

Hydraulic Unit. 30 kW (40 HP) SEW pump motor, 0.4 kW (0.5 HP) heat exchanger motor, 1.5 kW tank heater.

All motors are supplied with equipment. Motors, Starters, Variable frequency conveyor drives. Hydraulic unit motor starters and tank heater contractor are customer supplied.

ELECTRICAL INTERLOCKS

Discrete I/O interlocks.

Optional interlocks are available.

ELECTRICAL CONTROL

Allen Bradley Programmable Controller

Control Voltage. 24 VDC

Optional controllers available.

ELECTRICAL COMPONENTS

All components meet CE/UL/CSA standards

ELECTRICAL WIRING

Proximity Switches with Connectors. 0.21mm²-0.33mm² (24-22 AWG) stranded cable

Standard. 1.31 mm² (16 AWG) stranded cable

Primary. 3.31 mm² (12 AWG) stranded cable

PNEUMATICS

Required only for auto air blast feature and wire tension control

5.5-6.9 Bar, 28 L/min (80-100 PSIG, 1 SCFM)

MACHINE WEIGHT

8,181 kg (18,000lbs.)

1,182 kg (2,600lbs) with hydraulic fluid

HYDRAULIC UNIT WEIGHT

MACHINE HEIGHT

4,064 mm (160in.) standard

MACHINE WIDTH

4,572 mm (180in.) excluding coil carrier

MACHINE LENGTH

1,372 mm (54in.) conveyor gap

CONVEYOR

Chain Conveyor- powered forward/reverse, 27 MPM (90FPM)

STANDARD CONVEYOR HEIGHT

Minimum 585 mm (23in.)

HYDRAULICS

Self-contained hydraulic power unit using Parker directional valves and Oil Gear axial piston pump.

Air/Oil. Optional: water/oil

COOLING

Top Compactor. Up. 2,686mm (105-3/4in.) Down. 1,403mm (55-1/4in.)

Side Compactor. Side Out. 2,057mm (81in.) Side In. 991mm (39in.) Down

Optional compactor ranges available.

COMPACTOR OPENINGS

UNITIZING BENEFITS

SAFETY

4:1 Safety factor, stable stacking in ship cargo holds

COST SAVINGS

Minimal disposal packaging needed, no additional dunnage, high speed loading and discharge, and significantly reduces damage claims

EFFICIENCY

Lifting of multiple units, easy attachment and automatic unhooking of lifting devices.

RECYCLABLE

Easily recyclable galvanized wire, no pulp contamination, test documentation support available