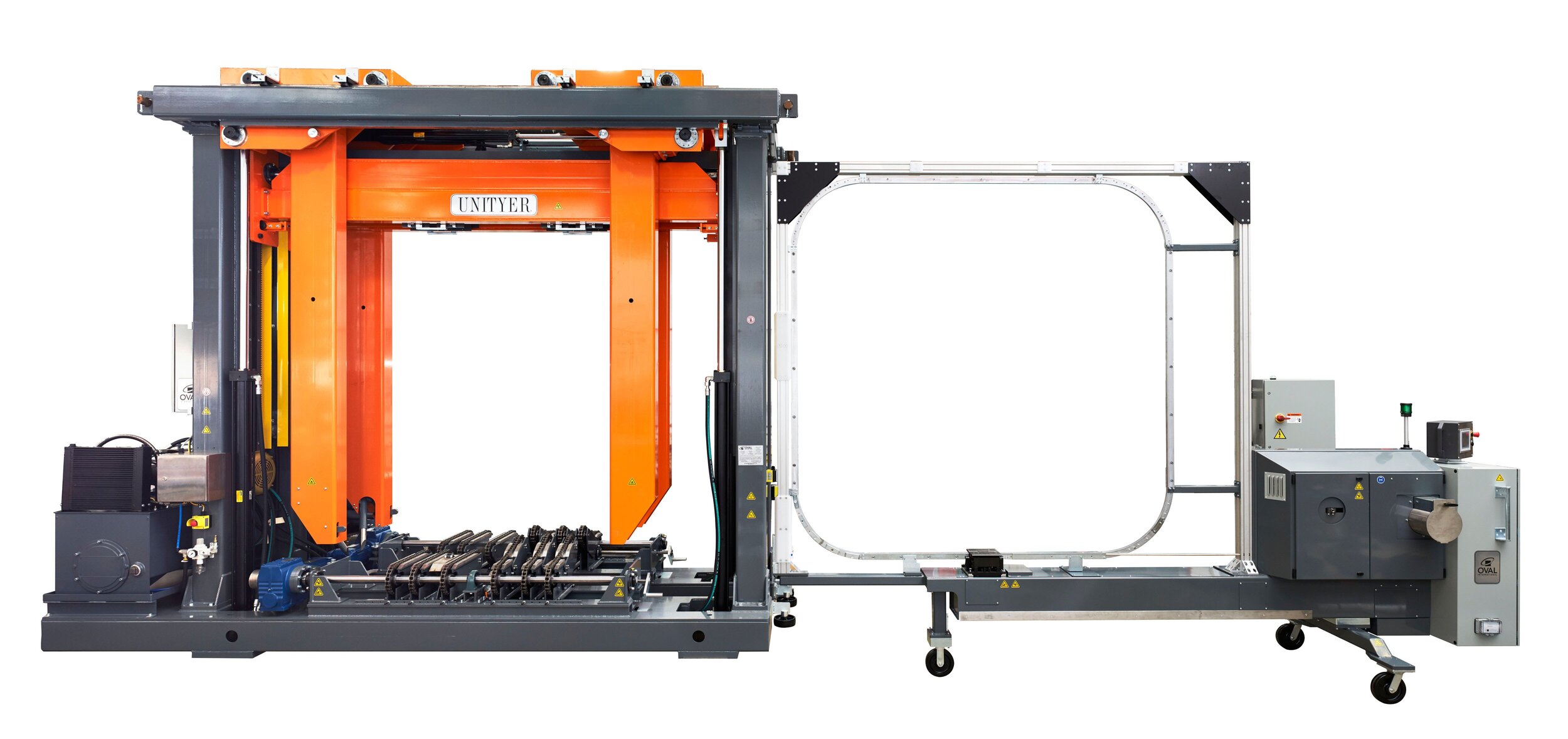

OVALMATIC

MODEL

E9700

UNITYER®

The model E700 Unityer comprises a removable all-electric Tying Unit and a hydraulically operated stationary Compacting Station. All tying functions are AC gear motor driven using AC Vector Drive technology. The E9700 Tying Unit includes automatic waste wire coiling for disposal, a high capacity accumulator and automatic threading after a coil change. The Compacting Station provides side and top compacting functions powered by a small on-board HPU.

Features and Benefits

ALL ELECTRIC WIRE TYING

Reduces potential problems and the environmental concerns of hydraulics.

ROTATING DISC ACCUMULATOR

High speed, accurate management of wire- virtually eliminates knots and jams.

AUTOMATIC WIRE THREADING

Simply inserting wire into the outer guide starts and completes the feeding sequence.

AC VECTOR MOTOR

Drives cams in twister head

Low cycle time

LOW FRICTION TRACK

The proven low friction passive track design requires no lubricants

ON BOARD PLC

Touch panel operator interface built in diagnostics

Safe 24 Volt DC controls

EASY ACCESS

Doors and panels allow easy accessibility for inspection and maintenance.

SEPARATING MACHINES

Tying machine is easily separated from Compacting Station for easy access and maintenance allowing standby machine to be used.

ROTATING DISC ACCUMULATOR

Provides complete control of wire feed and tensioning and accumulated wire

Reduces twists, buckles and jams

Standard Specifications

TYING WIRE RECOMMENDED

Ovalmatic® Quality Unitizing Wire

ELECTRICAL SERVICE

Unityer Tying Machine. 208-575 VAC, 3PH, 5KVA

Compacting Station. 208-575 VAC, 3PH, 50/60 Hz

Excluding conveyor and hydraulic unit power requirements.

ELECTRICAL MOTORS

Feed/Tension. 3.7 kW (5 HP) AC SEW gear motor

Accumulator. 0.75 kW (1 HP) AC SEW gear motor

Twister Head. 1.5 kW (2 HP) AC SEW gear motor

Tying machine motors are controlled by KEB closed loop vector drives.

Conveyor Drive. (2) 1.5 kW (2 HP) 208-575 VAC 3PH, 50/60Hz reversible SEW gear motor

Hydraulic Unit. 7.5 kW (10 HP) SEW pump motor, 0.4 kW (0.5 HP) heat exchanger motor; 1.5 kW tank heater.

All motors are supplied with equipment. Variable frequency conveyor drives, hydraulic unit motor starters and tank heater contractor are customer supplied.

ELECTIRCAL INTERLOCKS

Siemens Profibus.

Optional. Allen Bradley Ethernet IP ControlNet or Discrete 1/0 120VAC or 24VDC

ELECTRICAL CONTROL

Siemens series PLC

Control Voltage. 24 VDC

Tying machine motors are controlled by KEB closed loop motion control drives.

Optional. Allen Bradley Control Logix PLC with PanelView Plus Touchscreen

ELECTRICAL COMPONENTS

All components meet CE/UL/CUL standards.

ELECTRICAL WIRING

Proximity Switches with Connectors. 0.21-0.33mm2 (24-22 AWG) stranded cable

Standard. 0.52mm²-1.31mm² (20-16 AWG) stranded cable

Primary. 5.26mm²(10 AWG) stranded cable

PNEUMATICS

Required for auto air blast, electrical enclosure cooling

5.5-6.9 Bar, 1,130 L/min. (80-100PSIG, 40 SCFM)

Minimum Filtration Requirements. Particulate filtration to 5 Microns with moisture removal and oil removal to 1PPM. Instrument air is strongly recommended.

MACHINE WEIGHT

Tying Station. Standard Tying Machine. 1,180 kg (2,600 lbs.)

Compacting Station. 10,890 kg (24,000 lbs.) including hydraulic unit

MACHINE HEIGHT

3,849 mm (151 in.) at 585 mm (23 in.) minimum height (the overall height is determined by unit size and conveyor height)

MACHINE WIDTH

6,180 mm (243 in.) with tying unit engaged

HYDRAULICS

Self contained hydraulic power unit using Parker directional valves and Parker axial piston pump.

COOLING.

Air/Oil

CONVEYOR GAP.

1,372 mm (54 in.)

OVAL International® specifications are subject to change without notice.

OVALMATIC® COMPONENTS

The core of the Unityer is built on five Ovalmatic® components:

Feed and Tension Assembly

Twister Assembly

Track Assembly

Frame Assembly

Control Assembly

Each of these assemblies is designed to provide maximum accessibility for inspection and maintenance function.

ALL ELECTRIC DESIGN

All tying functions are electrically driven using AC vector drives technology

Automatic wire threading

Feeding

Tensioning

Accumulation

Gripping

Twisting

Cutting

Automatic Wire Cleaning